Through the experience gained in the die business, Yonetani offers services to customers to help support & improve the unique needs of each customer’s operations in design, process, inspection, and assembly. We welcome inquiries from all customers, not limited to just those in the casting business.

01

Please request processing of large machine parts and mold parts.

It supports cutting, electrical discharge machining, and wire electrical discharge machining. Supports iron-based materials (cast iron, hot die steel, stainless steel) and aluminum processing. Especially, it has strength in processing large parts.

02

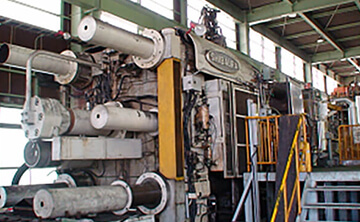

You can prototype aluminum die casting parts.

It is possible to manufacture aluminum prototype parts without stopping the mass production equipment. If you can get the 3D data of the product, we will independently provide parts from die analysis, design, casting, and processing.

03

It is possible to measure parts with complicated shapes.

It is possible to perform dimension verification for each drawing dimension by contact measurement and surface measurement of the entire shape by non-contact (laser) measurement.

Equipment

※H30.4.1

Head Office & Plant

| Brand | Equipment Name | Quantity | Table Size | Remarks | Zero Clamping System | |

|---|---|---|---|---|---|---|

| 5-face Machining Center | OKUMA | MCR-BⅡ 7000 |

1 | 3800×2000 | Add BC Axis | ○ |

| OKUMA | MCR-BⅡ E100 |

1 | 4800×2500 | Add BC Axis | ○ | |

| Gate type Machining Center | OKUMA | MCV-AⅡ | 1 | 1800×1200 | ○ | |

| OKUMA | MCV-A5000 | 1 | 1800×1000 | ○ | ||

| OKUMA | MDB | 1 | 1300×1000 | |||

| Machining Center | OKUMA | MC6V-5000 | 2 | 1530×630 | ○ | |

| OKUMA | MA-650VB | 1 | 1530×660 | ○ | ||

| OKUMA | MILLAC611VⅡ | 1 | 1600×610 | ○ | ||

| MAKINO | GF8 | 2 | 1800×800 | ○ | ||

| MAKINO | GF12 | 1 | 2150×1200 | ○ | ||

| MAKINO | v56i | 1 | 1050×550 | ○ | ||

| MAKINO | V99 | 1 | 1800×1000 | Temperature Control | ○ | |

| MAKINO | V99L | 2 | 2300×1000 | Temperature Control | ○ | |

| Machining Center | MAKINO | A77 | 1 | 730×730 | ○ | |

| MAKINO | A88 | 1 | 730×730 | ○ | ||

| MAKINO | a81nx | 2 | 630×630 | ○ | ||

| OKK | MC-8H | 1 | 800×800 | ○ | ||

| MAKINO | MCB1310 | 1 | 1000×1000 | ○ | ||

| OKK | HM1250S | 1 | 1250×1250 | ○ | ||

| MAKINO | MCC2013 | 1 | 2200×1000 | Temperature Control | ||

| Machining Center | KURAKI | KGD-2013A | 1 | 1800×1600 | Gun drill | ○ |

| 5-axis Machining Center | OKUMA HOWA | VMP-16 | 1 | 1200×1200 | ○ | |

| Machining Center for Graphite | MAKINO | SNC 86 | 2 | 1000×600 | ||

| MAKINO | SNC 106 | 2 | 1000×600 | |||

| MAKINO | v56iGR | 1 | 1050×550 | Long Z-Axis Stroke | ||

| EDM | MAKINO | EDNC 106 | 5 | 1300×950 | ||

| MAKINO | EDNC 106S | 1 | 1300×950 | |||

| Wire Cut EDM | MAKINO | U86 | 1 | 800×800 | ||

| SODICK | ALN800G | 1 | 800×600 | |||

| Turning Machine | HOWA | STRONG860 | 2 | φ100 | ||

| Milling Machine | NIIGATA | 6UM | 1 | 1400×720 | ||

| Milling Machine | MAKINO | DJU107 | 4 | 1700×500 | ||

| Grinding Machine | OKAMOTO | – | 1 | 600×300 | ||

| Drilling Machine | OOYA | RE | 2 | 800×500 | ||

| MIROKU | MEG-600 | 1 | 1000×500 | |||

| Turning Center | OKUMA | LB-300 | 1 | φ150 | ||

| Cutting Machine | TUNE | CS-400P | 1 | – | ||

| Cutting Machine | AMADA | V500 | 1 | 650×650 | ||

| Cutting Machine | FRIGGI | FG620-TS | 1 | 1300×500 |

Chubu Branch Office & Plant

| Brand | Equipment Name | Quantity | Table Size | Remarks | Zero Clamping System | |

|---|---|---|---|---|---|---|

| Machining Center | TOSHIBA | MPF-2114C | 1 | 1900×1500 | ||

| Machining Center | TOSHIBA | BMC-63E | 1 | 630×630 | ||

| EDM | MITSUBISHI | DIAX EA12 | 1 | 700×500 | ||

| Cutting Machine | AMADA | V400 | 1 | 600×600 |