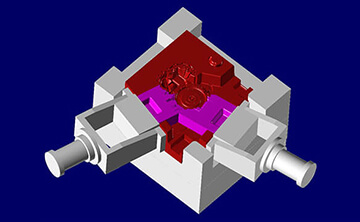

Incorporating a complete 3D design method, we can offer a speedy and dependable die design. Yonetani has a sufficient database and range of experience, which will enable us to offer optimized solutions to various customer requirements.

01

You can make a prototype with a mold at an early stage of product launch.

With a structure in which the special part and the general-purpose part are clearly separated, the mold is designed and manufactured only by manufacturing and recombining only the special part to shorten the manufacturing time.

Sand mold casting is used in the early stage of product trial production, but by producing parts from the mold with a lead time equivalent to that, it is possible to significantly shorten the entire product development(including the test period)…

02

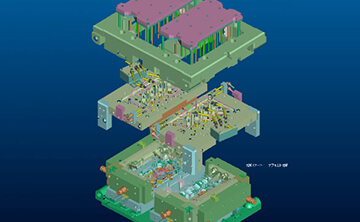

Data can be centralized in a complete 3D design, improving the quality of die production and shortening lead time.

With a complete 3D design, it is possible to study in advance the interference of parts and the assembly efficiency, and dramatically improve the efficiency of field work. In addition, since a bill of materials (BOM) is automatically created, it is possible to make a kit (preparation) of the parts that make up the die based on it, and prevent mistakes in the assembly of parts.

03

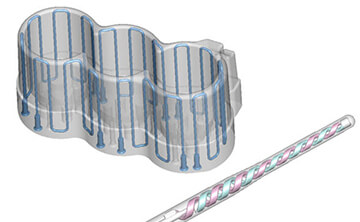

Product quality and molding cycle time can be greatly improved.

The role of “heat exchanger” is required for casting and die casting molds. It is possible to improve the internal quality and cycle time by cooling the mold quickly and in the right place.

However, molds with complicated cooling circuits tend to have poor maintainability, and we will design the mold while also considering workability improvement.

In addition, if cooling efficiency cannot be achieved by general hole processing alone, it is possible to manufacture mold parts with optimized cooling circuits using a 3D printer.

Software

CAD/CAM/CAE

| Type of Software | Brand | Quantity | Remarks |

|---|---|---|---|

| CAD(3D,2D) | PTC | 18 | Creo Parametric 2.0 |

| CAM(3D) | VERO JAPAN | 15 | WorkNC |

| CAM(3D) | Tebis | 2 | Tebis |

| CAE(Flow&Solidification) | TCS | 1 | TOPCast |

| CAE(Strength) | MSCJapan | 1 | Apex |

| CAE(Sand Core Filling) | Arena-FLow | 1 | Arena-Flow |