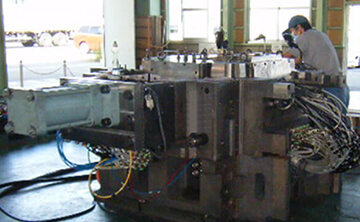

Yonetani has capability to design & manufacture dies for over 2,000tons discast machine. We are committed to out our best efforts to improve the process to achieve the most precise, safest and efficient die for customers total satisfaction for larger applications as well.

01

You can count on Yonetani for the stable supply of good quality dies

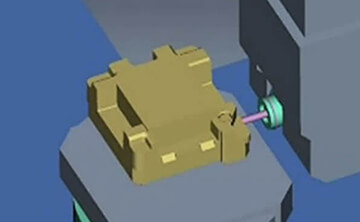

Before starting the actual machining, the tool and holder selection, setup method, and machine operation simulation on the computer are performed reliably to achieve stable long-term machining.

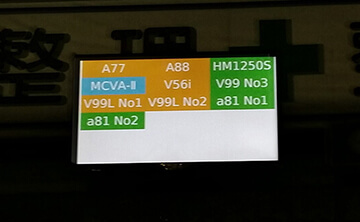

The operation of the machine tool is monitored by the IOT machine operation monitor to improve the mobility.

Not only can you monitor the operation of the machine, but you can also collect the causes of stoppages, so you can obtain detailed data for process improvement, contributing to improved productivity.

(The IOT machine operation monitor is an in-house system.)

02

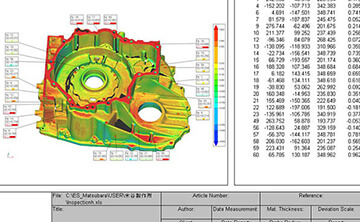

We will ensure the dimensional guarantee of molds and products, and we will consider reliable shape correction folding according to the tendency of dimensional difference of products.

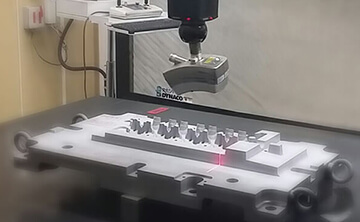

Using contact and non-contact three-dimensional measuring machines together, we strictly measure whether the product and mold dimensions meet the required tolerances, and prevent the outflow of defects.

We will collect the measurement results in a detailed report, share the information with the customer, and make a proposal to pass the first shot after the second type.

03

Please request for die modification, repair, and maintenance to Yonetani.

We can also repair and maintain large die castings of 2000t class. In the case of mold failure, we analyze the cause of the failure and perform accurate repairs unique to the mold manufacturer.

Equipment

※H30.4.1

Head Office & Plant

| Brand | Equipment Name | Quantity | Table Size | Remarks | Zero Clamping System | |

|---|---|---|---|---|---|---|

| 5-face Machining Center | OKUMA | MCR-BⅡ 7000 |

1 | 3800×2000 | Add BC Axis | ○ |

| OKUMA | MCR-BⅡ E100 |

1 | 4800×2500 | Add BC Axis | ○ | |

| Gate type Machining Center | OKUMA | MCV-AⅡ | 1 | 1800×1200 | ○ | |

| OKUMA | MCV-A5000 | 1 | 1800×1000 | ○ | ||

| OKUMA | MDB | 1 | 1300×1000 | |||

| Machining Center | OKUMA | MC6V-5000 | 2 | 1530×630 | ○ | |

| OKUMA | MA-650VB | 1 | 1530×660 | ○ | ||

| OKUMA | MILLAC611VⅡ | 1 | 1600×610 | ○ | ||

| MAKINO | GF8 | 2 | 1800×800 | ○ | ||

| MAKINO | GF12 | 1 | 2150×1200 | ○ | ||

| MAKINO | v56i | 1 | 1050×550 | ○ | ||

| MAKINO | V99 | 1 | 1800×1000 | Temperature Control | ○ | |

| MAKINO | V99L | 2 | 2300×1000 | Temperature Control | ○ | |

| Machining Center | MAKINO | A77 | 1 | 730×730 | ○ | |

| MAKINO | A88 | 1 | 730×730 | ○ | ||

| MAKINO | a81nx | 2 | 630×630 | ○ | ||

| OKK | MC-8H | 1 | 800×800 | ○ | ||

| MAKINO | MCB1310 | 1 | 1000×1000 | ○ | ||

| OKK | HM1250S | 1 | 1250×1250 | ○ | ||

| MAKINO | MCC2013 | 1 | 2200×1000 | Temperature Control | ||

| Machining Center | KURAKI | KGD-2013A | 1 | 1800×1600 | Gun drill | ○ |

| 5-axis Machining Center | OKUMA HOWA | VMP-16 | 1 | 1200×1200 | ○ | |

| Machining Center for Graphite | MAKINO | SNC 86 | 2 | 1000×600 | ||

| MAKINO | SNC 106 | 2 | 1000×600 | |||

| MAKINO | v56iGR | 1 | 1050×550 | Long Z-Axis Stroke | ||

| EDM | MAKINO | EDNC 106 | 5 | 1300×950 | ||

| MAKINO | EDNC 106S | 1 | 1300×950 | |||

| Wire Cut EDM | MAKINO | U86 | 1 | 800×800 | ||

| SODICK | ALN800G | 1 | 800×600 | |||

| Turning Machine | HOWA | STRONG860 | 2 | φ100 | ||

| Milling Machine | NIIGATA | 6UM | 1 | 1400×720 | ||

| Milling Machine | MAKINO | DJU107 | 4 | 1700×500 | ||

| Grinding Machine | OKAMOTO | – | 1 | 600×300 | ||

| Drilling Machine | OOYA | RE | 2 | 800×500 | ||

| MIROKU | MEG-600 | 1 | 1000×500 | |||

| Turning Center | OKUMA | LB-300 | 1 | φ150 | ||

| Cutting Machine | TUNE | CS-400P | 1 | – | ||

| Cutting Machine | AMADA | V500 | 1 | 650×650 | ||

| CMM | MITUTOYO | CRYSTA-Apex C 122010 | 1 | 1200×2000 | contact/non‐contact | |

| MITUTOYO | CRYSTA-Apex S 121210 | 1 | 1200×1200 | contact/non‐contact |

Chubu Branch Office & Plant

| Brand | Equipment Name | Quantity | Table Size | Remarks | Zero Clamping System | |

|---|---|---|---|---|---|---|

| Machining Center | TOSHIBA | MPF-2114C | 1 | 1900×1500 | ||

| Machining Center | TOSHIBA | BMC-63E | 1 | 630×630 | ||

| EDM | MITSUBISHI | DIAX EA12 | 1 | 700×500 | ||

| Cutting Machine | AMADA | V400 | 1 | 600×600 |